Sustainable Governance

Supply Chain Management

In a globally interconnected industry, we firmly believe that stable and reliable supplier partnerships are a key foundation for sustainable business operations. Yongdao is committed to building a safe, healthy, environmentally responsible, and human-rights-respecting supply chain. Through the Procurement and Quality Management departments, suppliers’ process capabilities and overall performance are regularly evaluated to ensure supply chain stability and consistent product quality.

We fully integrate corporate social responsibility (CSR) and ESG principles into our supplier management system. Evaluation criteria include quality, delivery performance, occupational safety, environmental management, and labor conditions. Currently, all raw material suppliers comply with RoHS (HSF) standards and have obtained international certifications such as ISO 9001:2015 Quality Management System, ISO 14001:2015 Environmental Management System, and ISO 45001:2018 Occupational Health and Safety Management System. By working together with Yongdao, suppliers help promote a responsible corporate ecosystem and realize sustainable value.

Global Compliance and Assurance

Our commitment to ethical performance is underpinned by strict adherence to global standards. We rigorously integrate ISO 9001, 14001, and 45001 requirements into our supplier selection, ensuring quality management, environmental responsibility, and occupational safety. Furthermore, we enforce a continuous Green Procurement Policy, ensuring 100% FSC certification for all major paper-based materials and antennas. To maintain product integrity and global market access, our chemical management systems strictly monitor hazardous substances in materials (RoHS) and comply with key regulations, including EU REACH, EU POPs, and the US TSCA. This commitment is validated by our participation in performance measurement programs like the Higg Index FEM self-assessment.

I. Supply Chain Management Policy and Actions

Arizon places great importance on the sustainable development of its supply chain and regards suppliers as key partners in maintaining long-term competitiveness. The Supply Chain Management Department and the Quality Management Department jointly implement supplier management and evaluation procedures. All raw material suppliers undergo a qualified supplier evaluation once every six months to ensure supply chain stability and product quality.

To strengthen supply chain risk management, new suppliers are required to complete a Supplier Survey Form and sign an Integrity Commitment Letter and an Environmental Commitment Letter during onboarding, committing to compliance with sustainability management requirements.

- Key and primary raw material suppliers are required to obtain ISO 9001 certification to ensure quality and supply stability.

- Raw material suppliers with higher environmental risks are required to obtain ISO 14001 certification to effectively manage the environmental impacts of raw material production processes.

In addition, Arizon recommends that all suppliers provide third-party verified environmental or social management system certifications as a basis for ESG risk assessment.

Arizon has established a Supplier Code of Ethics and Business Conduct, which covers corporate social responsibility policies, integrity and fair trade, labor rights, environmental responsibility, intellectual property and confidentiality obligations, and the prohibition of subcontracting. Through system improvement and enhanced transparency, Arizon aims to strengthen the overall competitiveness and sustainability of its supply chain.

In 2025, Arizon Yangzhou completed the signing of the Code of Conduct by 100% of its raw material suppliers, signifying a shared commitment between Arizon and its supply chain partners to ethics, compliance, environmental protection, and social responsibility, and laying an important foundation for building a more resilient and sustainable supply chain.

In addition, the procurement unit regularly tracks implementation results and reports them to the Sustainability Development Center to ensure effective execution of management policies and continuous improvement.

II. Evaluation and Guidance Mechanism

Arizon has implemented a multi-level supplier evaluation and guidance mechanism, including:

Annual Assessment

Key raw material qualified suppliers are assessed every six months. Assessment items include: supply quality, abnormality improvement and pricing, delivery and service, compliance with environmental commitments, operational safety, and labor conditions. The assessment is conducted in accordance with the Supplier Sustainability Assessment Guidelines. The Quality Assurance Department consolidates scores to complete the Qualified Supplier Performance Assessment Form, which, after approval by supervisors, is communicated to suppliers via the Supplier Sustainability Assessment Notification. Since full implementation in 2024, coverage has reached 100%, and the depth and breadth of self-assessment content will continue to be enhanced.

Annual On-site Audit

For key material suppliers with domestic production sites, an annual audit plan is established (Key Raw Material Supplier Annual Audit Plan). After approval by the authorized supervisor, on-site audits are conducted at the supplier locations according to the audit plan. Based on audit evaluation scores, rating levels are assigned, and corresponding improvement suggestions are provided.

- In 2025, 6 existing qualified suppliers were planned for audit and all 6 were actually audited, achieving a 100% completion rate. Audit results: 83.3% rated Excellent, 16.7% rated Good.

Arizon Yangzhou 2025 Execution Results

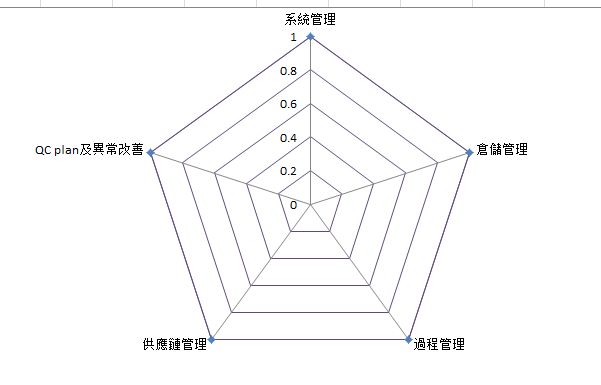

Audit items include system management, warehouse management, process management, supply chain management, QC Plan, and abnormality improvement. System management covers risk management, chemical and environmental management, and social responsibility.

Planned audits: 9 suppliers; completed audits: 8 suppliers; completion rate: 88.89% (expected to complete in December).

Audit results: 62.5% rated Excellent, 37.5% rated Good.

One new supplier was added, with audit result rated Good.

Subsequent management based on assessment results is as follows:

| Overall Score | Rating | Management Plan |

| 90 and above | Excellent | Reliable supplier; establish long-term partnership |

| 75 - 89 | Good | Areas for improvement; can maintain long-term procurement |

| 60 - 74 | Average | Supervise improvement; limited procurement; select backup suppliers |

| Below 60 | Poor | Disqualify as qualified supplier; select new supplier |

Supplier ESG Self-Assessment

In 2025, Arizon completed ESG self-assessments for all key suppliers. The assessment results will serve as an important basis for subsequent supply chain risk management and continuous improvement.

III. Our Sustainable Supply Chain Goal

Audit Coverage

Achieve 100% compliance in the planned supplier physical audit completion rate annually.

Supplier Declarations

Achieve 100% completion in signing all required Supplier Declarations to ensure ethical and environmental adherence across our material base.

Local Procurement

Proactively seek local suppliers to increase the local procurement proportion by 3.79% for key raw materials, strengthening regional economic resilience.

IV. Performance Results

In 2025, Arizon achieved significant results in sustainable supply chain management:

All three plants successfully established cooperation with three local suppliers in Taiwan, strengthening localized supply chains and reducing carbon emissions from international transportation.

- • Supplier evaluation pass rate: 100%

- • Regular assessment pass rate: 100%

- • Annual audit pass rate: 100%

- • Sustainability commitment clauses incorporated in supplier contracts: 100% compliance

V. Stakeholder Engagement and Continuous Improvement

Arizon values communication and collaboration with suppliers and continuously promotes quality improvement and operational optimization.

In 2025, a total of 25 quality review meetings were held across Arizon’s three plants, covering monthly supplier quality assessments, in-plant abnormality analysis, reliability verification, customer feedback, non-conformance reports (CAR), change requests (ECR/ECN), and special procurement handling. IQC, FQC, and IPQC quality processes were also reviewed. Each plant updated its risk and opportunity measures quarterly and conducted regular internal audits and management reviews to strengthen the effectiveness of the quality management system.

In the same year, Arizon Yangzhou held weekly quality review meetings and initiated improvement communications with suppliers based on supply performance as needed. Through monthly and semi-annual quality assessments and on-site audits, suppliers were assisted in continuously optimizing quality performance and improving overall management standards.