Employees & Society

Occupational Safety and Health

Safe and Healthy Working Environment

Arizon RFID Technology is a leading global provider of RFID electronic tag solutions. In pursuit of sustainable operations, we are committed to implementing workplace safety and occupational health practices, strengthening labor–management relations, and achieving shared objectives. We have accomplished the following key outcomes:

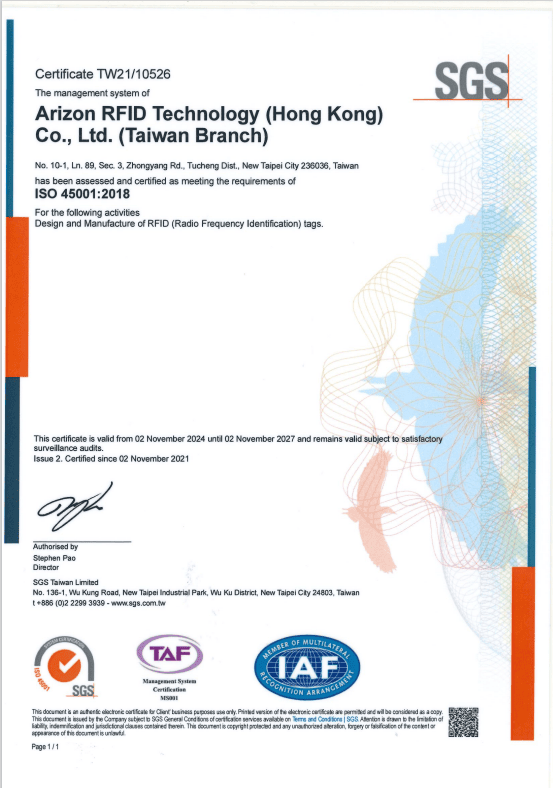

Implementation of an Occupational Safety and Health Management System with International Certification

Our manufacturing facilities have obtained international certification under the ISO 45001 Occupational Health and Safety Management System, ensuring a safe working environment. Dedicated occupational safety and health units have been established to promote and oversee related initiatives.

By following ISO guidelines, we prevent work-related injuries and illnesses and continuously improve occupational safety and health performance, thereby providing a safe and healthy workplace for all employees.

Brief History of Occupational Safety and Health Management System Certification

Improvements in Occupational Safety and Health Implementation

Safety and Health Supervision and Inspection Practices

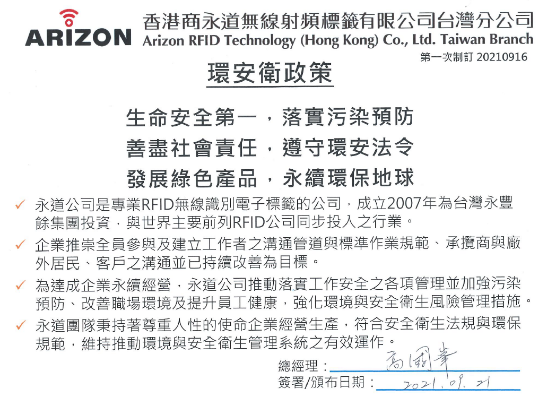

The Company has established an Environmental, Safety, and Health (ESH) Management Manual, which clearly defines management policies and objectives. These policies are communicated to all employees through multiple channels, including company bulletin boards and internal announcements. In addition, occupational health and safety and social responsibility considerations are incorporated into supply chain management, enabling the Company to work with its partners to jointly promote sustainable development.

An Occupational Safety and Health Committee has been set up at the plant, holding regular meetings to review and adjust occupational safety promotion and health enhancement programs. Employees are also able to participate in occupational safety and health decision-making through labor representatives. This approach ensures that OSH policies are closely aligned with on-site needs, with the goal of achieving a safe and healthy workplace for all employees.

Safety and Health Supervision and Inspection Practices

- Tiered Responsibility by Department

Dedicated occupational safety and health supervisors are appointed to provide guidance, oversight, and audits of occupational safety and health measures. - Promotion of Safe Operations

Safety education programs are implemented to strengthen safety management capabilities and foster a shared commitment to safe operations across the organization. - Standardization of Operating Procedures

Standard Operating Procedures (SOPs) are established for all operational activities to ensure consistent and safe work practices. - Employee Health Management

Regular employee health examinations are conducted, and health and hygiene education and training programs are planned and provided based on employee needs. - Safety Training for Personnel

All employees are required to complete safety training. In addition, on-the-job training and safety awareness programs are conducted periodically. - Incident Reporting and Investigation

In the event of an occupational accident, all facilities are required to report the incident to the responsible occupational safety and health personnel within 24 hours. Root cause investigations are conducted, corrective and preventive actions are implemented, and follow-up training is completed to prevent recurrence. - Safety Reviews and Emergency Response Drills

Safety reviews are conducted, and various emergency response and disaster prevention drills are carried out on a regular basis. - Occupational Safety and Health Audit Program

Annual self-inspection plans and occupational safety and health management plans are established. Detailed implementation measures, inspection methods, inspection cycles, and execution schedules are defined in accordance with the plans. Progress is reviewed monthly and reported during management review meetings to continuously enhance the effectiveness of occupational safety and health management.

Strengthening ESG Management and Safeguarding Employee Traffic Safety

ARIZON RFID Traffic Safety Training Program Report

-

People-Oriented Approach, Safety First

ARIZON RFID Technology places employee safety at the core of its ESG responsibilities. We are committed to continuously creating a safe and healthy working and commuting environment to protect the well-being of all employees.

- Professional Training with Ongoing Implementation

In July 2025, ARIZON RFID invited Officer Li from the Traffic Police Detachment of the Yangzhou Municipal Public Security Bureau to conduct a Traffic Safety Training Program for all employees in multiple sessions, reinforcing the company’s commitment to systematic and ongoing safety management. - Practical and Focused Training Content

The training covered safety regulations for electric scooters and motor vehicles, analysis of real traffic accident cases, and practical daily commuting safety tips. The program aimed to strengthen employees’ risk awareness, preventive measures, and emergency response capabilities. -

Shared Commitment to Safety and Continuous Improvement

Safety is the cornerstone of family well-being and corporate stability. ARIZON RFID will continue to deepen its ESG management practices by integrating safety principles into daily operations and working collaboratively to build a safe and sustainable operating environment.

Embedding ESG Principles and Strengthening the Safety Defense Line

ARIZON RFID 2025 “Safety Production Month” Activity Review

-

Safety First: Fulfilling ESG Responsibilities

ARIZON RFID regards safety as both a fundamental business principle and a core social responsibility. In response to the 24th “Safety Production Month,” the company translated ESG principles into concrete actions across its operations.

-

Firefighting Drills to Enhance Emergency Response Capabilities

The local Fire Brigade was invited to conduct on-site “Six Familiarizations” practical drills at the manufacturing facilities. These exercises enhanced firefighting and rescue plans and strengthened the professional emergency response capabilities of the on-site mini fire stations.

-

Health Promotion: Caring for Employees’ Physical and Mental Well-being

Guided by the principles of ESG sustainable development, the Company regards employees’ physical and mental well-being and occupational safety as key priorities of its corporate social responsibility. By introducing professional occupational health and safety consulting resources, the Company continuously enhances health promotion initiatives and workplace environment management, striving to create a safe, healthy, and sustainable working environment.

-

Professional Training to Enhance Safety Competence

Targeted training programs were conducted for safety officers, focusing on case studies and hazard identification. These initiatives strengthened risk recognition and emergency handling capabilities in key positions.

-

Company-wide Participation to Build a Practical Safety Shield

Company-wide evacuation and firefighting drills were organized, covering day and night shifts as well as external personnel. These activities promoted the practical implementation of the principle: “Everyone values safety, and everyone is prepared to respond to emergencies.”

-

Long-term Safety Commitment and Continuous Management Enhancement

While “Safety Production Month” has concluded, ARIZON RFID’s commitment to safety management continues. The company will persist in strengthening ESG governance, safeguarding employee well-being, and supporting long-term sustainable development.

| Category | Hazard Identification & Risk Assessment | Improvement Measures | Site |

| Occupational Safety & Health Priority Actions | Chemical Hazards | Installation of additional spill containment trays, installation of additional exhaust ventilation equipment, and monitoring of workplace environmental parameters. | Taipei Plant 3 |

| Friction-induced overheating leading to bearing seizure |

Replacement of faulty motor bearings with new motors; installation of paper break detection and filtration devices to prevent kraft paper belts from jamming motor bearings. | Taipei Plant 3 | |

| Uneven pavement in front of the security office | Completion of asphalt resurfacing to repair damaged pavement, achieving 100% completion. | Taipei Plant 3 | |

| Lack of direct-access stairway in the office building | Safety inspection identified the need to install a second direct-access stairway. | Taipei Plant 3 | |

| High prevalence of metabolic syndrome identified in employee health examinations |

Procured blood pressure monitors, increased the frequency of health education and training, and issued health management announcements. |

Taipei Plant 3 |

|

| Chemical explosion-proof storage |

Chemicals are stored in explosion-proof cabinets that meet safety standards; storage quantities are controlled at the minimum safe operational level to reduce explosion risks. |

Yangzhou Plant |

|

| Chemical waste liquid collection |

Installed additional spill containment trays and exhaust ventilation equipment. |

Yangzhou Plant |

|

| Establishment of safety inspection management mechanisms |

Continuously implemented defined safety inspection responsibilities and frequencies to strengthen safety supervision. Inspection results are tracked through the safety inspection system, with nonconformities corrected within specified timelines to ensure closed-loop management. | Yangzhou Plant |

| Category | Hazard Identification & Risk Assessment | Improvement Measures | Site |

| Site Safety Improvements | Traffic Safety | In-depth training on safe driving practices for non-motorized vehicles and motor vehicles. | Yangzhou Plant |

| Regular Internal Audits |

Internal audits serve as a critical mechanism for continuous improvement and risk management. Through systematic reviews and corrective actions, ESG sustainable governance is effectively implemented. | Taipei Plant 3 | |

| Emergency Response |

Through hands-on operations and regular emergency drills, combined with corrective and preventive actions for nonconformities, personnel emergency response capabilities and reporting procedures are comprehensively strengthened to ensure incidents are handled promptly and safely. | Yangzhou Plant |

| Task Group |

Task Principles |

Equipment, Materials, and Data |

| Command Personnel (Disaster Prevention Center and Command Posts) |

Monitor fire situation, direct firefighting, oversee equipment and evacuation, ensure safe refuge. | Fire protection plan covering fire monitoring, firefighting instructions, equipment supervision, and safe evacuation; includes team leader roster, piping and electrical diagrams, employee roster, and command, lighting, and protective equipment to ensure comprehensive emergency response. |

| Communication Team |

Upon fire detection, immediately notify fire department, conduct internal reporting, contact relevant personnel, and perform at least two orderly emergency broadcasts to prevent panic. |

Emergency contact lists, broadcast scripts, radios, telephones, megaphones; gloves, rubber boots, fire helmets, and identification vests; use floor plans to guide safe evacuation. |

| Firefighting Team |

In the initial stage of fire, if flames have not reached the ceiling, use fire extinguishers, buckets, or indoor fire hydrants under the supervision of the team leader; assist fire department as needed. | Fire extinguishers, fire hydrants, hoses with nozzles, breaching tools, communication devices; gloves, rubber boots, fire helmets, identification vests; floor plans to guide safe firefighting and evacuation. |

| Evacuation Guidance Team |

Place guides at fire floors, stairwell entrances, corridor corners, and elevator lobbies; use safe evacuation routes, prioritize evacuation from hazardous areas, open evacuation doors in advance, guide personnel to fire-safe zones, ensure no one is left behind before retreating. |

Keys, megaphones, ropes, resident roster, signage, lighting, communication equipment; gloves, rubber boots, fire helmets, identification vests; use floor plans to guide safe evacuation. |

| Safety Protection Team |

Close fire doors and rolling doors, shut down HVAC, activate smoke exhaust systems, stop elevator operation, isolate hazardous materials, ensure emergency power, disable ignition sources, establish restricted zones. |

Building, fire, and electrical diagrams; breaching tools, fire door and elevator keys, waterproof tarps or spare sprinklers, ropes, communication equipment; gloves, rubber boots, fire helmets, identification vests; use floor plans to ensure safe operation and evacuation. |

| First Aid Team |

Set up emergency medical station staffed by CPR-qualified personnel; prepare medical supplies and equipment; triage and treat injured personnel; coordinate with fire department and provide patient lists and status. |

Emergency medicines, first aid kits, stretchers, medical station equipment, injury record forms, communication devices; gloves, rubber boots, fire helmets, identification vests; use floor plans to guide emergency medical care and evacuation. |