SOLUTIONS

RFID Supplier Material Management Platform

Real-Time Data, Total Supply Chain Control.

In today's fast-paced supply chain, managing material flow and information flow must be perfectly synchronized. Our RFID Supplier Material Management Platform provides the optimal solution, bridging the gap between production and dispatch.

This powerful system features cloud synchronization and actual label printing, ensuring both the accuracy and immediacy of all outbound shipments.

We strongly recommend pairing this with the RFID Receiver Material Management Platform. Together, these two systems eliminate information asymmetry, drastically expedite the issuing and receiving process, enable true real-time goods tracking, and virtually eliminate human errors.

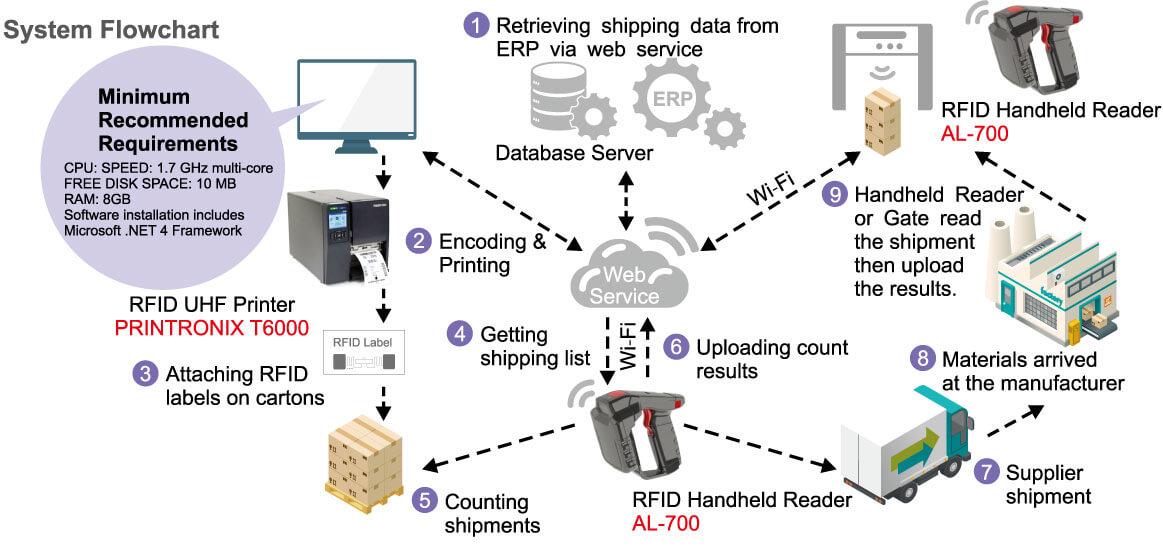

How it Works

Core Advantages

Real-Time Information

Instantly update data across your entire supply chain for faster decisions.

Increase Efficiency

Streamline dispatch processes and reduce processing time at every stage.

Reduced Human Error

Automate data capture and verification, minimizing costly manual mistakes.

Cloud Integration

Ensure all partners and systems are working with the same, up-to-date data.

Immediate Accuracy

Guarantee shipment accuracy right at the source with validated label printing.

Application Areas and Using Benefits

Global Manufacturer Integration

Effortlessly integrate material source manufacturers into a single, cohesive management system.

Reduced Operational Costs

Minimize operation overhead and significantly reduce human errors through systematic automation

Enhanced Working Efficiencies

Increase overall productivity by standardizing processes and eliminating information lags.

Centralized Management Platform

Utilize a systematic, unified platform for consistent data capture and superior control.

Maximized Information Transparency

Increase visibility for all stakeholders, providing a complete, auditable view of material movement.

Accurate Stock Status

Keep up with accurate, real-time stock status, supporting better production planning and minimizing bottlenecks.