Sustainable Governance

Product Sustainability

The durability and reliability of RFID tags may be affected by various environmental, physical, chemical, and electromagnetic interferences. These impacts may lead to tag failure, reading difficulties, or data errors, preventing long-term stable operation. Such issues can increase customers’ processing risks, reduce production efficiency, and ultimately affect customer satisfaction and corporate competitiveness.

Policy Commitments

- Integrity and Ethics

All members of the YD team uphold correct values, act with honesty and integrity, refrain from deception or falsification, and take full responsibility for the products they deliver. - Trust and Reliability

We build product credibility through superior quality, zero defects, high reliability, and precise delivery schedules. - Excellence and Innovation

We stay aligned with the latest technological capabilities, continuously surpass existing standards, develop new business models, and create greater value for our customers.

Actions Taken

- Strictly implement product development and mass production processes to ensure all products undergo DV, EV, PV, and FMP stages, with 100% completion of product reliability testing to guarantee stability and reliability.

- Establish a comprehensive inspection process covering IQC, FAI, IPQC, and FQC, enabling full-process monitoring and ensuring each production stage meets specification requirements and quality standards.

- Conduct rigorous reliability verification for both new and mass-produced products in accordance with the most stringent industry standards, ensuring stable and reliable performance for every batch.

- Regularly review standards and procedures, evaluate the effectiveness of quality inspections, and develop process training materials to enhance employee skills. Production yield rates and inspection data are analyzed to ensure effective implementation of all quality requirements.

- Continuously monitor and improve product quality through internal audits and finished product inspection records, ensuring all production processes comply with specifications and promoting quality management and continuous improvement.

Evaluation Mechanism

- 100% of new products must pass PV review.

- Inspection data is collected and analyzed, with weekly quality meetings held to review results and implement improvements.

Objectives

-

Short-term Goals

-

- 100% of mass-produced products pass reliability testing.

- 100% of shipped products pass full-process inspections.

-

Mid- to Long-term Goals

-

- Enhance failure analysis capabilities and continuously improve product quality.

Performance Results

- 100% of shipped products passed full-process inspections.

- Reliability test pass rate for mass-produced products: 100%.

Product Marketing and Labeling

All products of Arizon. not only meet customers’ stringent quality requirements but are also provided with appropriate packaging and comprehensive product information labeling in accordance with applicable regulations. This includes detailed disclosures such as raw materials, substance composition, and product specification and safety documentation.

In 2025, the Company recorded no incidents of non-compliance with laws and regulations related to product and service information, labeling, or marketing communications.

Requirements for Product and Service Information and Labeling

| Source of Product Components / Materials |

Based on the Bill of Materials (BOM) list and individual raw material suppliers. |

| Product Content and Composition | Referenced from the Safety Data Sheets (SDS) of each raw material. SDS documents disclose the substance composition and proportion of each material. |

| Product or Service Usage Safety |

Referenced from the SDS of individual raw materials. |

| Product Disposal and Environmental / Social Impacts |

Referenced from product specification documents. |

Customer Relationship Management

Arizon RFID Technology (Cayman) Co., Ltd. adheres to the principles of Integrity, Trustworthiness, and Innovation, adopting a customer-centric approach with the core objective of meeting customer needs and enhancing customer satisfaction.

To improve customer satisfaction, the Company conducts annual customer satisfaction surveys to understand customer perspectives and gather feedback on product pricing, product quality, service quality, and delivery performance. “Customer Satisfaction Questionnaires” are distributed via email or fax, inviting customers to evaluate product and service quality. Survey results are compiled, recorded, and archived, serving as a reference for business strategy formulation and business development enhancement. Continuous improvements are implemented based on the survey outcomes to strengthen product quality and service performance.

In addition, the Company regularly conducts customer business meetings, technical meetings, product quality control discussions, product lifecycle management activities, product exhibitions, reciprocal visits, new product introductions, and exchanges on industry competitiveness, information security, customer audits, inspections, and site visits. These initiatives enhance customer engagement and foster long-term, stable cooperative relationships.

Actions Taken

- Conduct customer satisfaction surveys twice annually to promptly understand customer feedback and implement continuous improvement measures based on the results.

- Establish multiple communication and feedback channels to reduce communication time costs and improve efficiency between customers and the Company.

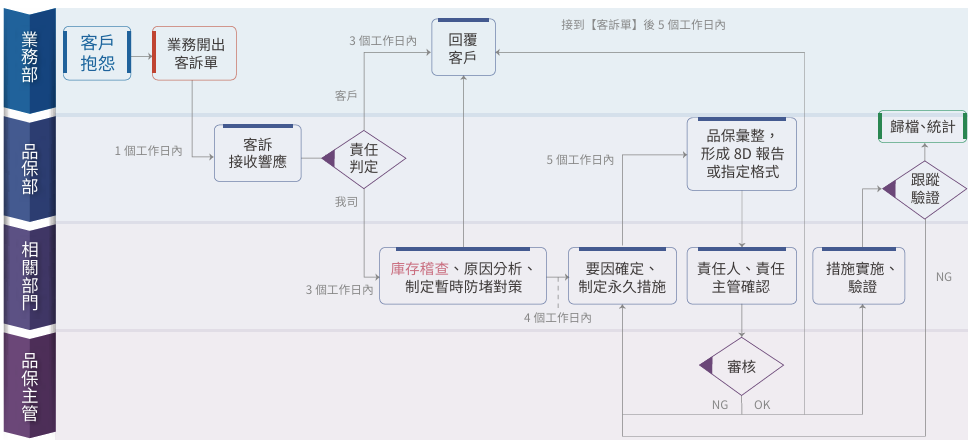

- Implement a customer complaint and product analysis system to systematically analyze root causes and corrective actions for each reported case.

Customer Complaint Handling Process and Customer Grievance Channels

Customer Complaint Handling Process and Customer Grievance Channels

Customer Communication Channels

Mainland China Business:

Sales Department – Ms. Yuan

Tel: +86-514-8097-2024 Ext. 15457

Email:Business@Arizonrfid.com

Taipei Business:

Sales Department – Ms. Chen

Tel: +886-2-2322-4824 Ext. 132

Email:Business@Arizonrfid.com